About SigMaSense

The manufacturing industry is on the edge of a fundamental structural change. We are witnessing a paradigm shift from considering single, isolated production steps to a holistic treatment of products along their entire life cycle. This vision, often referred to as 'Industry 4.0', has become a major driver of innovation for the entire sector.

It comes with a significant potential of improving the efficiency of the resource usage, facilitating flexible production and operation processes, and enhancing the overall sustainability, which underlines the inevitability of facing this transformation.

It becomes increasingly evident that such a change requires a fundamental rethinking of how data is acquired in this context. Classical techniques for nondestructive testing (NDT) turn out to be too inflexible for this task. Even more so, merely scaling them to the context of digitalized manufacturing inevitably leads to massive amount of data that can barely be handled and that are highly redundant.

From the viewpoint of digital signal processing, this creates the urgent necessity to render the acquisition and processing of material data as efficient and redundancy-free as possible. Instead of accumulating massive amounts of 'big data' blindly, we should aim at identifying the significant part of it ('relevant data' or 'smart data') already in the acquisition step. We are expecting a significant potential for this idea since existing NDT techniques are still directly based on their analogue predecessors. Novel insights in modern signal processing, which allow to overcome classical criteria such as the Nyquist condition, have not been applied in the NDT field yet.

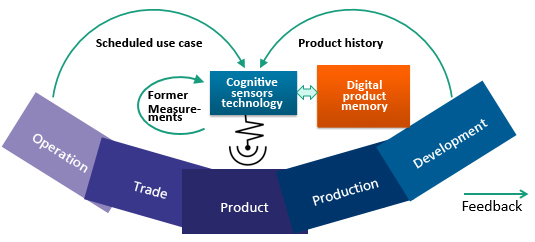

The group SigMaSense (signal processing for material data acquisition using smart sensors) is devoted to this field of research. To this end, it employs innovative signal acquisition techniques such as compressive sensing, which allow to reduce the data redundancy by a substantial amount, leveraging prior knowledge about the object under investigation. In so doing, sensing systems can adapt to various degrees of prior knowledge and become cognitive, enabling them to optimize and parameterize themselves autonomously in order to obtain the current required information with minimal effort. In order to process and interpret the data, the SigMaSense group applies innovative signal processing techniques such as model-based imaging, sparse signal recovery and multimodal data fusion.

Core Concept Cognitive Sensors Technology: Exploiting Prior Knowledge

- - Group Objective is the development of novel cognitive sensors technology

- • Extraction of Intelligent Material Data

- • Exploits Prior Knowledge of Digital Product Memory

- • Adds further Information continuously

- • Based on Innovative Signal Acquisition Concepts (Compressed Sensing)

- - Core Competence Compressed Sensing

- • Low-redundancy Signal Acquisition, Hybrid Analog-Digital Architectures, Reconstruction Processes: Computational Imaging, Sparsity-promoting Inversion, Model-based Imaging

- - Furthermore, vast Experience in the Field of Signal Processing

- • Multidimensional Signal Processing (Tensors, Multilinear Algebra)

- • Statistical Signal Processing (esp. Estimation Theory)

- • High-resolution Parametric Estimation